WHAT DOES POWER CONTROL MODULE DO?

Ever since the carburetor gave out its last breath the Power Control Module has been developing.

For the purposes of this blog post I will be referring to Charles White’s Automotive Engine Management Systems and fuel injection Techbook as published in 1997 by © Haynes publishing. I cannot recommend this book enough, its goal is to be your handy partner into the world of PCM.

I. Naming.

There have been so many names given and so many variations that it is hard to keep track. Let me try and list some of the names given to the PCMs in history:

- PCM – Powertrain Control Module.

- ECM – Engine Control Module.

- ECU - Engine Control Unit.

- PCU - Powertrain Control Unit.

- PMU – Powertrain Management Unit.

- DME- Digital Motor Electronics

- Thousands of other variations, all meaning the same thing. An electronic controller who’s job it is to manage the Engine and sometimes other drivetrain components like the transmission.

II. Function.

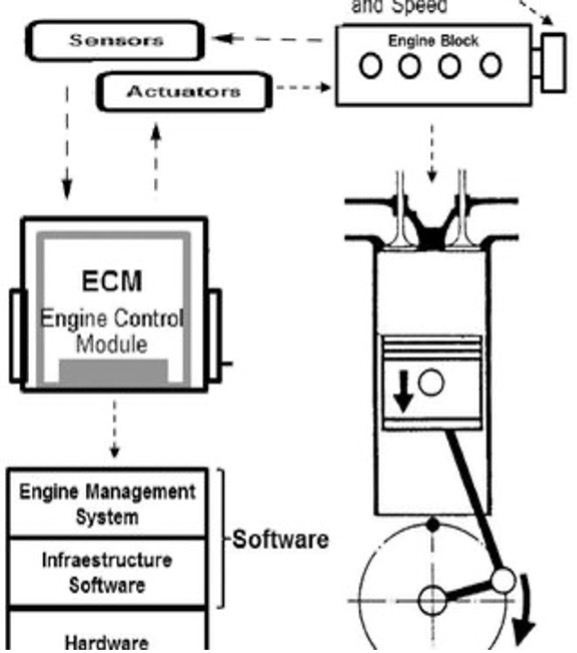

Today we will focus on the controller which controls the engine. Let’s take at how the control of the engine functions. Here is what is going on:

The engine is the beating heart. The ECM is the brain responsible for it. It gathers information about the engine using sensors attached to it and uses this information to control how the engine operates – it takes the position and speed of the crankshaft, the amount of air going in, the air pressure and the quality of the fuel coming in to determine when to fire the ignition, when to modify the amount of fuel sprayed by the injectors, ignition timing advance and retard. The ECM achieves all of these by a combination of software and hardware. On the one hand we have the hardware – this is a printed circuit board (PCB) with all the inputs from the engine (and the rest of the modules) going into it, at the figurative center we have a processor, which is responsible for processing the information needed in order to perform the best calculations to achieve maximum performance and fuel efficiency in the current conditions. One of the best parts of the ECM is the ability to set defenses to protect your car’s engine both as an OEM manufacturer and your local tuner. For example, if the knock sensor senses detonation the ECM will retard timing. If the variable valve timing is not working correctly- it will do the same, if the mixture becomes too lean. This is a pre-programmed logic by the manufacturer or tuner.

III. Variations.

You will find all kinds of variations out there, sometimes there is a master and slave ECM, because the manufacturer built a V8 by combining two 4 cylinders in a common crank case, V10 by to two five cylinders, W16 by 2 VR8s, etc.

There are water cooled ECMs, internal EEPROM, external EEPROM types, ECMs which control multiple drivetrain components, security ones, ones that allow programming, standalone ECUs and all thousands of variations. I will see you soon, my dear readers, until then – try to have fun at work.

Alek

ADI (Instrument Cluster and Display) Configuration

ADI (Instrument Cluster and Display) Configuration TCU Personalization Without FBS4 Data

TCU Personalization Without FBS4 Data

Instrument Cluster Data Manager (IC, BSI,

Instrument Cluster Data Manager (IC, BSI,