MULTI POINT INJECTION (MPI) VS. DIRECT INJECTION (DI)

I. What is the difference?

Advancements in fuel injection have led us in developing multiple directions of injecting fuel into the combustion chambers. When it comes to the difference between multi-point injection and Direct Injection is the difference between the position of the injectors. The MPI injectors are located before the intake valves where it sprays the fuel in the intake of the engine and the suction created by the piston sucks the atomized fuel with the air through the intake valve opening, essentially spraying in the intake port. Direct injection is different because it (as the name suggests) is directly installed inside the combustion chamber next to the spark plug. Direct injection allows for the fuel to be injected into the combustion chamber with much higher pressure and the control over the spray pattern and the exact moment of injection is very much easier to control. There are many positives of having both systems, but also some drawbacks. What are the differences between direct injection vs port injection? What is the goal of an MPI engine?

Here is what PORT INJECTION (MPI) looks like:

The air and fuel get mixed before entering the chamber and they enter at high velocity as the piston draws the mixture through the open intake valve.

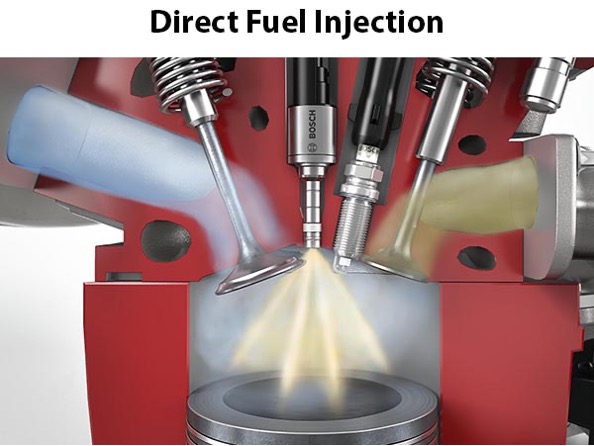

Here is what DIRECT INJECTION looks like:

The injector is placed directly into the combustion chamber. Clean air enters the combustion chamber and vert precise regulation of the fuel delivery is possible. What is an MPI engine? - It is an engine which has an injector for each cylinder or even more in some cases. This is what MPI means in cars, boats, trucks and everything with an engine.

II. Advantages and disadvantages of direct vs port injection

1. Fuel economy – manufacturers love to tell you that this engine is 13.4345% more economical than the previous version because they have now incorporated direct injection you can regulate a lot more and be more efficient, skip cycles, etc.

2. You can incorporate flat shifting or managing the engine in such a way that it cuts fuel and spark super precisely so that you can shift a manual car with DI without ever lifting your foot off the gas and not even touching the clutch. You can tune infinitely; you can even kill 50% of your cylinders safely by killing spark and spray to be more economical under less load. If you have port injection this is a bit harder to achieve.

3. Port injection allows for a clean intake tract because it inherently cleans it with fuel. In direct injection applications the intakes are usually dirtier because of the oil vapors, this causes carbon buildup and eventually requires cleanup such as walnut blasting, chemical cleaning, or even disassembly to clean. Serious damage can occur if the carbon buildup is left unchecked.

4. Injector prices. Injector prices for port injectors are lower when compared to direct injectors. This leads me to understanding injector buzzwords you will hear a lot:

- Low impedance injectors – these allow to be more precise – fast start and stop of the spray, higher velocity spray pattern (usually the impedance is between 2 and 4.5 Ohms).

- High impedance injectors – from 8 to 16 Ohms – the difference between the two is the best use of your coil which will allow you to spray the optimal amount of fuel for your application to stay open until the current stops (less precise).

- Piezo injectors – these are a Bosch revolution – they use piezo crystals on one side and using precise electrical current the crystal material expands and shrinks in order to let fuel trough, this leads to super detailed operation and high fuel velocity, but they are more expensive than conventional actuator (solenoid type) injectors.

III. Back in my day.

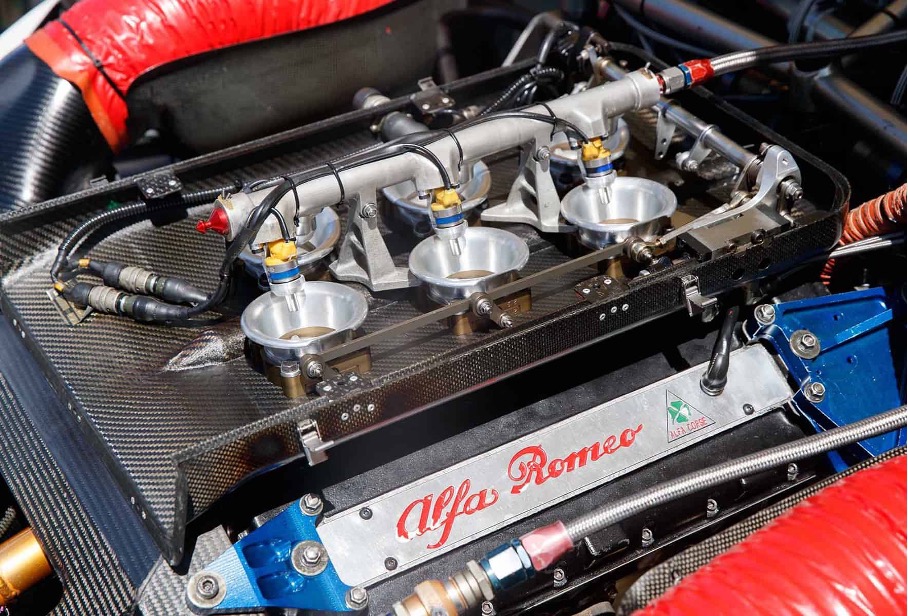

I will finish this tale off with a story from history – the Alfa Romeo 155 2.5 V6 TI DTM – a mouthful, I know, but the car was worth it. Here you can see a bespoke 2.5 liter mega high revving (12,000 RPM) engine with a 60° angle, nothing to do with the other Alfa Romeo 60° engine installed in the street 155s – the BUSSO. So anyway, the dry-sump DTM wasp of a V6 was an outstanding bit of kit for the times it worked, and it worked pretty well from 1993 to 1996 for Nicola Larini and Alessandro Nannini who in total with the other drivers managed to pull together 38 wins from the 68 races in the 3 years the car was campaigned. I always wondered what the secret behind the 490HP naturally aspirated low volume engine was and I always thought it was just rev it to the moon and send it. It wasn’t until a couple of years ago when I was reading about these cars again that I came across an interesting picture of the engine without the carbon air box. It was interesting to me because the V6 sat so low in the chassis that a dry sump was even too much (it basically used pressure oiling with external dry sump (ahead of their time, really), but what I noticed was the picture below. The engine was equipped with individual throttle bodies (ITBs), of course, any N/A racing engine is, but what I wondered about was the placement of the injectors and it turned out that the injectors were placed above the trumpets of the ITB (short for high top end power) in order to have (what the Italian engineers referred to as) “longer time for the fuel to mix with the air and better atomize the air fuel mixture”. WOW! I had never really thought about that but in the period between 1989 when Alfa decided to campaign this car in the Deutsche Tourenwagen Meisterschaft and 1993 when the car won 11 races someone tested this theory and they eventually put to action to achieve something which can only sound so incredible. An 11,900 RPM, 2.5 liter V6 that made 490 horsepower and dominated the Tedeschi at their own game (I still love you, E30 M3, don’t leave me :D )

Until next time, try to have fun at work,

Alek

ADI (Instrument Cluster and Display) Configuration

ADI (Instrument Cluster and Display) Configuration TCU Personalization Without FBS4 Data

TCU Personalization Without FBS4 Data

Instrument Cluster Data Manager (IC, BSI,

Instrument Cluster Data Manager (IC, BSI,