MOTORSPORT DIAGNOSTICS – BEYOND THE CUTTING EDGE.

PART 1: WIRING

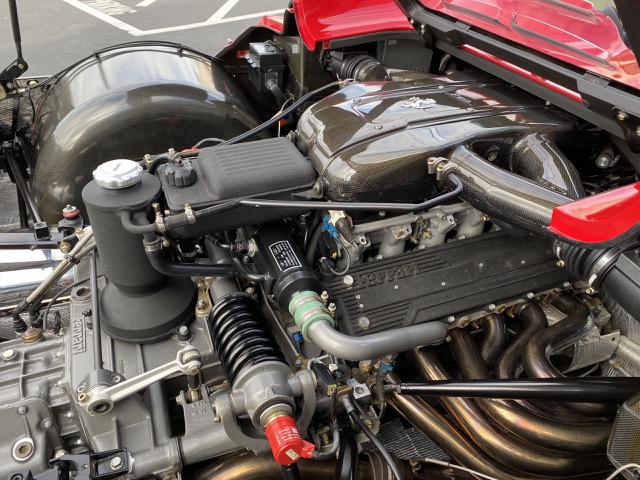

Since the beginning of time all new comfort features in automotive design have been demonstrated in the Mercedes S- class. Later it became commonplace in any Peugeot 208. The A/C, electric windows and what not have all had their start in an S class. Motorsport on the other hand gave the World all the things that matter in a vehicle. The parallel between the S class and racing cars is the exact reason why we all love cars. The fact that they are both similar and universes apart is the variety I love about cars. Historically motorsports have been the proving ground for new technologies since the beginning of time. Only the fastest survive, extreme technology, extreme speed and durability is what you need to be the best and run beyond the cutting edge. Oddly enough motorsport derived cars rarely work on the streets. They prove a bit too harsh for the Jetsetters who can afford them. The structure of the race car is very different to what they feel comfortable with so even though manufacturers love to say that something is motorsports derived this is more of a marketing trick than any real race car. The closest examples we had to “Race cars for the road” (a cliché motoring journalists love to use) were the Group A rally legends of the late 80s, early 90s like the Lancia Delta Integrale, the Ford Escort Cosworth, Toyota Celica GT Four, Subaru Impreza, Mitsubishi Lancer EVO 1 to 9… Due to the FIA’s regulations these were the closest to the real deal you could possibly get, and still the road versions were so much departed and watered down that you would swear it is not even funny. Now credit where it is due – Ferrari once got really close. The F50… a car so ferocious with its hard mounted V12, so exhilarating, exciting, and unforgiving that… almost no one wanted it. You see racing cars do not work on the road and even if the ones who afford it say they want them what they really want is bragging rights and Bugatti Chirons, yet most essential technology in your auntie’s Dacia exists because of motorsport.

I. History

Since the olden days people always wanted to go fast, running, horses, boats, ox and then there were cars. Ever since the invention of the motor vehicle we wanted to see who had the faster one. Nobody truly knows when it all began but the first organized motorsports events were either bootlegger who competed against each other or early versions of rallying.

In early motorsport days when rallying was little more than a road trip with checkpoints the vehicles were equipped with nothing but a small stopwatch and a map to tell the driver and co-driver where and how to be and at what time. It is safe to say that we have moved a lot since then. Receiving feedback about the state of a vehicle has evolved very much, however there are some artefacts that remain because of their simplicity. Remember, durability and ease of use just like military or aerospace. So for example even though brake disk temperatures are a thing in endurance racing we still use the simple temperature paint where each color burns off at a certain temperature, also adhesive thermometers are still in operation today. Motorsports rely on whatever works best for the certain application.

II. Wiring and modules used in 2023.

1. Wiring.

The nervous system of any vehicle, the stronger it is – the better you perform in any sport.

You see, there is so much we can talk about wiring harnesses that I will bore you to death. The most important thing in motorsports wiring is durability. We will refer to this nervous system as a wiring harness.

a. Wires.

Light- weight, highly conductive, well protected.

Each motorsport harness starts with a solid ground wire serving as the backbone of the wiring harness. The quality of the ground wire is very important, as is the quality of all other wires, they must be the best because being able to transmit the electrical current over it under any conditions – heat, cold, water, sand, gravel is what matters. For this reason, motorsports applications rely on Tefzel, GXL, SXL, TXL wires which are made of the highest-grade conducting materials. The metal inside these is often referred to as the best possible, pure silver, copper, gold, or aluminum but what helps these sometimes-precious metals conduct current uninterrupted is the coating. Tefzel and TXL refers only to the coating of each strain of wire, these are sometimes more expensive that the conductor itself and are made mostly of ethylene-tetrafluoroethylene materials which are much thinner than regular insulation much more durable. Durability is key and the fact that these coatings can endure over 150°C is what matters here. Tefzel and TXL are name brands which became synonymous with the materials. Fiber optics are also used nowadays but often due to their composition they are not as durable and are therefor less common.

b. Insulation.

Motorsports wiring also uses special Polyamide tape, often referred to as “Kapton tape” due to the name of the original manufacturer. The difference between this tape and the Tesa from the hardware store is the hear insulation it provides. Polyamide tape can take upwards of 400°C which is exactly what you need to protect your harness – overkill. After that you are looking at the heat shrink. Using heat shrink increases the chance of a harness staying dry and adds durability to flex of your harness. Next you have a very fashionable term, called concentric twisting. Concentric twisting is the result of a process where all the sensor and activator wires are twisted around the ground wire using a power drill to make the harness more flexible. This is not an easy task because you need to plan the length and position of your sensor wires, injector wires, coil wires and basically all the objects you are running the wires to. It looks pretty and some experts even add dummy wires to the harnesses to create colorful patterns for the added aesthetics. This is not the main goal; the main goal is to add strength and durability to your harness. In real motorsports the whole harness is then secured one more time in super high-grade oil, coolant and heat resistance heat shrink wires which protect it once again. Motorsport heat shrink can withstand temperatures from minimum of -80°C to over + 150°C of fluids in case your oil line goes boom in the arctic circle.

c. Connectors.

After you have protected your top-quality wires, you require special connectors. In modern times the connectors used in motorsports are pretty. No, no, no, just kidding… Well, they are but what they mostly are is durable. I am sure that you have often heard the term “MIL-SPEC” when referring to connectors, but what does it mean? MIL- SPEC is just an abbreviation for Military specification. Many motorsport technologies are military, and aerospace derived so the connectors are just that – derived from military technology because of the severe environments they are designed to operate in. They are normally composed of a mating pair (male- female socket-pin relationship), have a durable outside casing made of anodized aluminum or other durable metal alloy, connectors themselves consist most commonly of special materials such as phosphor-bronze or beryllium-copper and lock using a fine cut twist locking mechanism. They can have many types depending on the purpose they serve – wall mounted, angled cut, with or without a jam nut… The combinations are endless. Recently we started seeing composite connector housings which, as a certain recent submarine accident showed, is suboptimal. Minimal requirements are -80°C to 200°C, water and oil resistance and ease of operation even in an underwater scenario.

d. Terminals.

Connecting the cables to the connectors are the terminals, again quality is key here because having a loose terminal is strictly unacceptable. For this reason, soldering is not often used, rather crimping is the preferred method here, if you must use solder then the soldering cup is the way to go because it basically makes the terminal one with the cable. The so-called THT or through hole technology is what you mostly see when terminating motorsports wiring harnesses.

e. Sensors.

There is no point in any of the above unless your sensors are high quality, so once again – road car sensors are a compromise, rather only top-notch sensors are used. They are like the ones found in your car, only much more durable, made of better materials and ready for many more cycles. As with connectors, the technology for sensors is military derived. Sensors you will find in motorsport are like what you will find in a road car, only more durable and more precise. More expensive is a given. Here is what you will have:

- Fluid pressure sensors – these measure the pressure of the vital fluids in a vehicle like oil, coolant, brake fluid, fuel pressure.

• Air pressure – intake air pressure, exhaust pressure, boost pressure.

• Temperature sensors – exhaust gas, intake air, charge air, brake temps, oil, coolant, even fuel temp.

• Lambda sensors -designed to measure the quantity of oxygen in the exhaust gases to determine the ideal proportion of fuel/air for the optimal operation of the internal combustion engine.

• Knock sensors -even though they are often commonplace in most modern road cars that were once a racing specific application – knock sensors are stethoscopes listening for detonation in the cylinders of the ICE.

• Rotary position sensors – also known as TPS or throttle position sensors tell you where the flap on the throttle is.

• Positioning/ Speed sensors – crank and cam positioning sensors are the essential sensors for the operation of an ICE, they are there to determine the position of the crank shaft to determine TDC (top dead center) and the relation to the camshafts. They are basically magnets which usually look for a “missing tooth” on the crank sprocket. They use the Hall principle but this time they also care. Wheel speed sensors also use the same application, they count the number of times the missing tooth passes by the magnet.

• Vehicle dynamics sensors – these are the sensors measuring all three axis of movement of a vehicle and really only have application in motorsports, while some road cars have them they are little more than pub talking points there “My GT-R pulled 1.11175 cornering Gs while I was getting milk the other day is their only use in a road car”.

• Fuel quality sensors – these have much relevance to road cars as they are used to retard and advance timing and firing based on the fuel quality you are currently running. They can also determine ethanol content, but these are often called flex-fuel sensors.

• Transponders – these are great positioning sensors which measure lap times every time you pass the start-finish line. All but obsolete today due to the addition of precise military derived GPS.

These are the sensors you have and everything else is based on them. They keep both road and racing cars running.

f. Labeling.

There are very good and cheap label makers, they allow you to print simple labels to tell you what wire does what. Adding transparent heat shrink over these labels will give you longevity. This is the icing on the cake.

g. Ignition coils

– once again much higher quality than anything on a road car with maximum precision of ignition, spark force and durability. Far ahead of popular AUDI TFSI or R35 GTR coils so popular in tuner cars.

h. Relays, fuses and actuators

– each of these deserve a separate blog but we do not want to be here all weekend so just think of the simplest circuit, minimal amount of components involved and highest possible quality. We will touch more on them in the controller chapter.

i. Injectors.

Modern motorsport injectors are more precise than their road counterparts, they can have variable flow, spray patterns and respond to input much faster. This allows for precise combustion. High or low impedance injectors are employed. Huge volumes may be used due to Ethanol, Methanol and other fuels which reduce detonation.

To complete the wiring section of this blog post I must tell you that like the human body wiring harnesses are made in circuits, like the human nervous system, there is the central nervous system and the peripheral – let’s say the central system is the engine harness and the peripheral are the transmission, brakes, traction control, even comfort. This segmentation is designed for ease of operation and repair. If you are well prepared in a motorsport environment, you can easily replace a smaller harness. Having a separate harness for each system with the benefit of a quick disconnect will allow you to easily remove powertrain segments like engines, transmissions, and differentials because they are all connected via Mil- Spec connectors and run separate power and grounds. Most motorsports harnesses built to this quality are very expensive. They cost thousands over thousands and most of them are never reused. Overkill to the Nth degree? No, just risk management. Motorsports punishes any error, however minor it may seem, so when you have sponsors, teams, investors, millions, sometimes billions, riding on a race only the best will do.

Alek

ADI (Instrument Cluster and Display) Configuration

ADI (Instrument Cluster and Display) Configuration TCU Personalization Without FBS4 Data

TCU Personalization Without FBS4 Data

Instrument Cluster Data Manager (IC, BSI,

Instrument Cluster Data Manager (IC, BSI,